Feature Story

More feature stories by year:

2024

2023

2022

2021

2020

2019

2018

2017

2016

2015

2014

2013

2012

2011

2010

2009

2008

2007

2006

2005

2004

2003

2002

2001

2000

1999

1998

![]() Return to: 2015 Feature Stories

Return to: 2015 Feature Stories

CLIENT: CAMBRIOS

July 16, 2015: IEEE Computing Now

By Sri Peruvemba

While there seems to be a constant stream of technical breakthroughs in computing systems, particularly in processors, memory and faster interfaces, revolutionary changes are also occurring in display and touch technology.

To wit: greater touch sensitivity, enhanced luminance, bendable touchscreens, wraparound screens and dramatically lower cost, environmentally-sustainable manufacturing of silver nanowire-based touch screens. All are factors pushing indium tin oxide (ITO) to the side. Like dial up modems, manual transmissions and wired LANs, ITO's limitations don't work for 'what's next.'

New materials are triggering a wave of innovation in personal electronics. Driving these changes are incredibly small, highly-integrated and far easier to program microcontrollers and flexible circuit boards combined with silver nanowire-based touch screen technology.

And now touch screen displays no longer have to be flat. Flat and rigid are out. Curved and flexible are in. Additionally, most touchscreens require high-quality transparent conductors to provide a rich user experience. These features are being applied to products that will make today's tablet computers appear as dated as desktops and help push portable computing into entirely new sectors and price points. Kiosks, gaming machines, point-of-sale devices, automobile displays and medical devices are a few key categories ripe for adoption.

Flexible displays definitely equate to improved ergonomics. Imagine unbreakable phone screens that flex instead of shattering when dropped. Consider folding a tablet so it slips into your pocket like a mobile phone. How about a display that wraps around your wrist, or a huge public display wrapping around a pillar or the corner of a building like neon lighting does? We are driving toward products like these and they are creating increasing demand for flexible, bendable and rollable displays using silver nanowires.

Some likely next products include but aren't limited to: curved, shaped smartphones, flexible tablets as well as wearable smart bracelets and watches. Such products are specifically enabled by flexible device technology.

They are highly conductive single crystal silver nanowires suspended in a fluid/ink. These silver nanowires have a diameter of a few tens of nanometers and length of a few tens of micrometers, giving them a high (1000:1) aspect ratio. The ink is a mixture of highly conductive silver nanowires and other materials to enable the ink to be coated on all kinds of surfaces particularly plastic film. Using this ink to cover a screen creates a touch surface that is the most responsive as silver is the best electrical conductor in the world. Silver nanowire based touch sensors can work in touch screens on a wrist watch to touch screens on a large signage display.

SNW ink is also particularly transparent, has very good clarity and very little haze, making it ideal for displays requiring sharp, crisp images. Also, screen resistance can be customized to suit the specifications of individual OEMs and designers which allows for variable response times. Touchscreens can be used for devices, such as phones and tablets or big touch screen TVs or even exterior electronic signage. Perhaps most interestingly they can also be used in applications requiring round surfaces or conformity to angles, giving them a clear edge over conventional material which cannot bend.

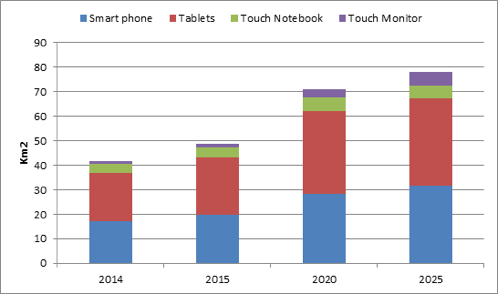

As reported in MIT Technology Review and elsewhere, SNW inks are being used in all-in-one computers and monitors made by LG, Lenovo, Dell, HP, and others. The material is also found in mobile phones and tablets made by NEC in Japan, Karbonn in India and Huawei in China. According to electronics research firm, IDTechEx, worldwide shipments of touch screen panels will double in area from 2014 to 2025 (see figure 2). Silver nanowires are also being adopted as the transparent-conductor-of-choice by leading industry heavyweights including Hitachi, LG, TPK, Nissha, 3M, Okura, CNI and others.

Figure 1: Touchscreen growth by surface area. Data courtesy- Dr. Khasha Ghaffarzadeh, IDTechEx Research

For emerging touchscreen applications, including large-area signage and monitors, as well as miniature, flexible, wearable displays, silver nanowires offer significant advantages both in cost and performance. The material is already being used in several consumer electronics products. Roll-to-roll processed silver nanowire transparent conductors are the clear choice for new factories needing high throughput, fewer consumables and easy processing. They're also on target for CE OEMs needing a thin, light, bright, flexible material delivering high performance for their next killer application.

Sri Peruvemba is a Vice President at Cambrios Technologies Corp. Cambrios provides innovative solutions using nanotechnology. Its silver nanowire-based transparent conductors simplify electronics manufacturing and improve end-product cost and performance for electronic devices. Cambrios is headquartered in Silicon Valley.

Return to: 2015 Feature Stories