Feature Story

More feature stories by year:

2024

2023

2022

2021

2020

2019

2018

2017

2016

2015

2014

2013

2012

2011

2010

2009

2008

2007

2006

2005

2004

2003

2002

2001

2000

1999

1998

![]() Return to: 2015 Feature Stories

Return to: 2015 Feature Stories

CLIENT: IDTECHEX

July 31, 2015: IEEE Computing Now

by Dr Peter Harrop, Chairman and Principal Analyst, IDTechEx Research

Conventional vehicles with an internal combustion engine as the sole traction power have become more electric over the years – as customers demand more and more electrical and electronic devices. Consider the increase in number of electric servo motors and actuators for seat adjustment, remote opening of the trunk and a multitude of other features now available. Then add to that the increase in electronics, such as new telematics, larger displays and more entertainment functionality – and we begin to see the larger picture. This trend continues with 2015 models sometimes having an inductive charging system for mobile phones and stop-start systems that are becoming the norm. Already, the battery can sometimes have a drain of 500W.

The increase in electrification will continue. For example, the Torque Assist Reversing Alternator (TARA) systems near to market introduction need to store the harvested energy and deliver it rapidly on demand. Other new energy harvesting modes are being introduced as well, such as energy harvesting shock absorbers and variants providing active suspension. Photovoltaics will increasingly make an impact too.

It all adds up to a need for more power to be stored on a conventional vehicle (even in some conventional small ships and aircraft). These vehicles do not have electric motors drive the wheels unassisted some or all of the time so they are not considered "electric vehicles." Nonetheless they are increasingly electric.

There are three popular ways of increasing the amount of energy storage: Enlarge the 12V battery; add a lithium-ion 48V battery and distribution system; or add the lithium-ion battery alone.

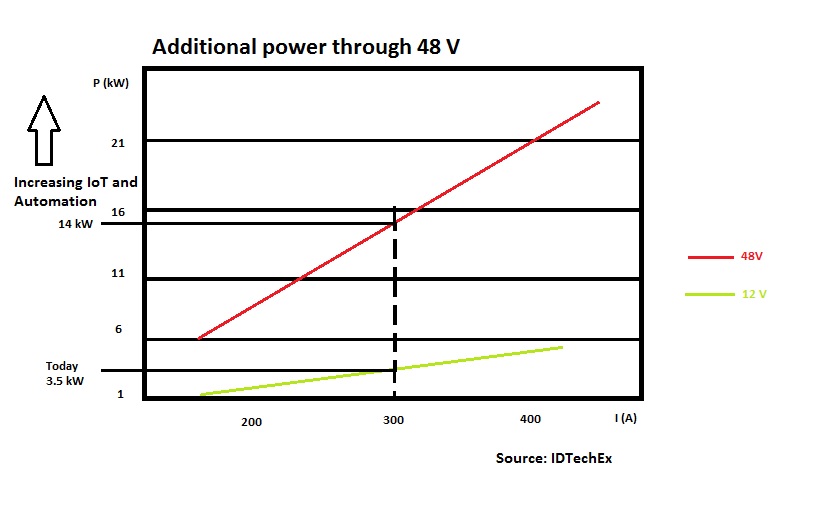

In each case a supercapacitor may be added to give better power density in and out and sometimes protect the battery. The reasons that make the 48V attractive include the ability to increase the voltage to reduce losses in the distribution system in the vehicle and yet stay under the 60V threshold, where regulations become onerous.

Many Tier One suppliers and OEMs in the automotive industry are keen to get into 48V conventional vehicle systems. Some have indicated that affordable 48V components are needed from reputable large suppliers - but that will be solved and 48V conventional vehicles will be commonplace within five years. Indeed, Audi has reported that future vehicles will use a dual 12V/48V system, which they say will also pave the way for new technologies to make vehicles more sporty, efficient and convenient to use.

For electric vehicles, voltage trends have been moving inexorably upwards in order to capture efficiency now that high-voltage motors are viable. The slowest to move have been saturated (old) markets like golf carts often staying at 24V. Next come maxi-scooters typically at 74V and hybrid and pure electric cars at 100V up to the 375V of Tesla models with some of the most advanced technology in volume production. Then we have Hummer, Frazer Nash and the 2014 hybrid Ferrari "LaFerrari" top performance car at 500-550V; in addition to record-breaking motorcycles and cars, experimental agricultural vehicles and road vehicles (such as buses and military vehicles) at 650-700V.

Nonetheless, a contrarian approach is coming in with the European Community FP7 SAFEDRIVE program seeking low voltage such as 48V to make it easier for small OEMs to make small volume industrial and other EVs. A common platform is sought for small cars, heavy goods and utility vehicles.

On the other hand, separately Renault and Valeo develop 48V systems to save cost and a Nissan interview conducted by IDTechEx Research in late 2014 revealed that most of the large car companies are eyeing this possibility for when the components become affordable. We're less optimistic about 48V EV systems in EVs beyond those using lead acid batteries such as golf carts and some car-like microEVs. For example, golf carts are variously on 24V, 36V and 48V systems in the main. In larger vehicles 48V may find some place, however.

Learn more in Santa Clara, California, Nov. 18-19 at Electric Vehicles: Everything Is Changing at the 2015 IDTechEx Show.

Return to: 2015 Feature Stories