Feature Story

More feature stories by year:

2024

2023

2022

2021

2020

2019

2018

2017

2016

2015

2014

2013

2012

2011

2010

2009

2008

2007

2006

2005

2004

2003

2002

2001

2000

1999

1998

Return to: 2015 Feature Stories

Return to: 2015 Feature Stories

CLIENT: IDTECHEX

Aug. 18, 2015: EE Times

Rachel Gordon, Technology Analyst, IDTechEx

The thermal interface material market will grow to $3 billion in 2025, according to analysts at IDTechEx Research.

Endless advances in electronics are changing every aspect of our lives. Consumers demand devices that are faster, thinner, and lighter while being reliable. This means higher density, higher power electronics, especially in smaller wearable technology devices. But this leads to more heat building up from the components, which damages and degrades the electronics. As a result, this problem is leading to a large opportunity for materials that can manage heat generation better -- known as thermal interface materials (TIMs) -- and, as a result, enable electronics to operate faster.

The thermal interface material market will be $1.3 billion in 2015 according to IDTechEx Research in the report, Thermal Interface Materials 2015-2025: Status, Opportunities and Market Forecasts, and it will grow to $3 billion in 2025.

When thermal management first started to become an issue, the choice of materials on offer was limited. Thermal grease was used to fill gaps between power devices and heat sinks. Manufacturing with greases is messy and imprecise, so while thermal greases remain popular in industrial computing and consumer electronics, they are experiencing decreasing market share.

Over time, thermal pads made from a silicone elastomer and electrically conductive fillers began to emerge. These are cleaner, easier to use, and more precise. These pads fill air voids between mating parts when subjected to assembly pressures from clips or screws and exhibit continually improving thermal performance over time as further flowing of the material occurs. Pads of this kind will be the most widely used thermal interface material by 2025.

It is also common to attach the circuit board to a larger heat sink or to the metal chassis of the product itself. The key to achieving successful heat transfer is to have a thin interface able to fill all air voids, such as a thermally conductive tape. These double-sided adhesive materials combine high structural bond strength and good heat transfer characteristics. Products are available for different thicknesses and surface areas of the mating parts.

In addition to these polymeric TIMs, there is also a wide range of metallic thermal interface materials available. Although lead solders can no longer be used due to toxicity, indium and gallium alloys are increasingly popular.

However, finding the right thermal management solution is not simple. Different applications have different requirements, which drive the choice of thermal interface material. As a result, the variety and breadth of thermal materials available and emerging today is broadening.

Traditionally, TIMs have been micro-structured, but R&D is increasingly focussed on nano-structuring. This can involve:

However, the TIM industry is conservative. Change is only ever considered when the current technology has reached its absolute limit and the substitute must itself be mature. Nevertheless, the consumer demand for increasingly smaller and faster electronics will drive new innovations and result in the market for thermal interface materials growing by 7.9% CAGR over the next decade.

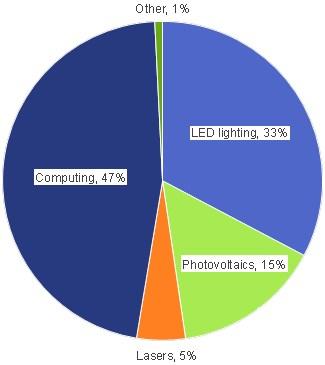

The following figure shows the predicted market share for Thermal Interface Materials in 2015, with computing (including wearables) being the largest market followed by LED lighting.

Predicted market share for Thermal Interface Materials (TIMs) by technology in 2015 (Source: IDTechEx Research, 'Thermal Interface Materials 2015-2025').

This and other materials opportunities will be covered at the IDTechEx Printed Electronics USA conference and exhibition, which will take place November 18-19, 2015, in Santa Clare, California.

Return to: 2015 Feature Stories