Feature Story

More feature stories by year:

2024

2023

2022

2021

2020

2019

2018

2017

2016

2015

2014

2013

2012

2011

2010

2009

2008

2007

2006

2005

2004

2003

2002

2001

2000

1999

1998

Return to: 2015 Feature Stories

Return to: 2015 Feature Stories

CLIENT: IDTECHEX

September/October 2015: North American Clean Energy

By Dr. Xiaoxi He

Perovskite photovoltaics are a breath of fresh air in the photovoltaic market.

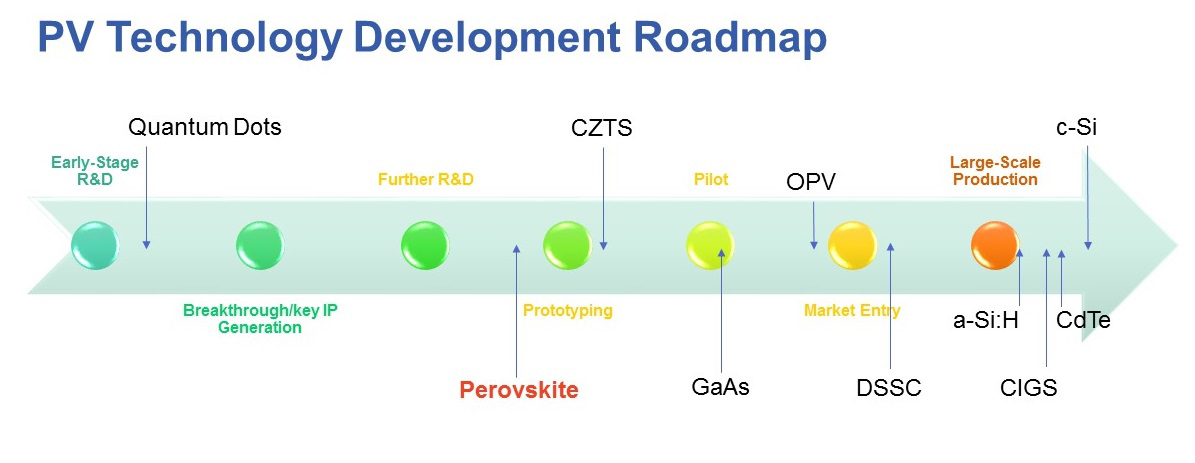

Perovskite photovoltaics are a breath of fresh air in the photovoltaic market.They have experienced a remarkable improvement from 2.2% efficiency – how much of the light energy is used by the system per unit area - in 2006, (Toin University of Yokohama) to the latest record of 20.1% in 2014 (Korean Research Institute of Chemical Technology KRICT, according to the latest efficiency records provided by the National Renewable Energy Laboratory (NREL) in the US). Perovskites have already surpassed organic photovoltaics (OPVs) and dye-sensitized solar cells (DSSCs) and are now, at least in terms of efficiency, in the same range as leading thin film PVs like cadmium telluride (CdTe) and copper indium gallium selenide (CIGS).

High and rapidly improved efficiencies are not the only advantage of perovskite solar cells. Flexibility, semi-transparency, tailored form factors, better low-intensity light performance, low potential processing cost, and low material cost are other value propositions of perovskite solar cells. It's no wonder why many companies and research institutions are strongly pursuing the technology.

Perovskite solar cells are often compared to CdTe solar cells, which have the lowest manufacturing cost among thin-film photovoltaic technologies. CdTe reported manufacturing costs of US$ 0.54 W-1 (or US$ 72 m-2) in the last quarter of 2013, for an average efficiency of 13.4%, where "other material" costs (which exclude semiconductor materials) are the majority. Those costs include glass sheets, junction boxes, tabbing, encapsulates, sealants, and tempered glass back sheets. There is no large reduction potential for the price per unit area due to the manufacturing cost limit, which is predominantly determined by "other material" costs. Outside of the module cost itself, (i.e., other hardware costs such as the balance-of-system costs) perovskite PVs have no advantage over c-Si cells or other commercial thin-film PV cells.

However, in terms of the semiconductor material cost, the active material cost of perovskites can be cheaper due to the lower cost of perovskite materials compared with CdTe. As the efficiency is further improved, the cost-per-watt can be decreased further.

Perovskite solar cells will not compete with the dominate c-Si cells in the short term due to their lack of maturity. Instead, however, perovskite solar cells can be combined with c-Si cells to further increase efficiency. By adding a perovskite solar cell on top of a c-Si cell, the total efficiency can be improved to as high as 30%.

In roof integrated installations where space is limited, the way to increase output is to improve the efficiency. The c-Si PV market is hugely competitive now, which means that any improvement in efficiency will help manufacturers distinguish themselves. The strong grid-connected market drive explains why most companies working on perovskite solar cells are targeting the utility market where the panels can be used in rooftop systems or mounted on the ground.

Perovskite solar cells can be integrated into glass and used for building integrated photovoltaic (BIPV) applications as well. Their use in smart glass may appear as one of the early applications of stand-alone perovskite solar cells, its transparency differentiating it from c-Si roof panels.

In addition, some companies are also targeting consumer electronics, wearables, and third-world application markets where the flexibility feature is a key added-value.

Most perovskite companies claim they will have first module prototypes near 2017, and enter the market in 2018. However, there are some barriers in the perovskite systems.

The biggest issue is the stability, or long term durability, of perovskite PVs. For example, the most common perovskite material used as the absorber is CH3NH3PbI3. It degrades in humid conditions and forms PbI2 at higher temperatures due to the loss of CH3NH3I. The materials degrade in standard environmental conditions, leading to efficiency and performance drops.

Studies shows perovskite solar cells can maintain more than 80% of its initial efficiency after 500 hours, but after 1,000 hours have minimal efficiency.

Therefore, applications in utility and BIPV will be unfeasible if the stability issue cannot be solved. Some companies have claimed that glass-on-glass encapsulation will be used so it can solve most of the stability problem and extend the lifetime. But long lifetimes have not yet been demonstrated with glass encapsulation.

The next big concern is toxicity. CH3NH3PbI3 can convert to PbI2 when in contact with polar solvents such as water. PbI2, moderately water-soluble, is a carcinogen and is banned in many countries. Lead-free perovskite solar cells can only achieve an efficiency of about 6% today. That means, unless new non-toxic material systems or good flexible barriers are found, the current toxic perovskite system will be difficult to use in consumer electronics applications, where they would otherwise offer a compelling benefit over other PV technologies because perovskites could be cheaper and more flexible. For this reason, many companies chose to sacrifice its potential flexibility, as encapsulation in glass can prevent the harm of toxicity. In addition, similar to CdTe systems, recycling is needed when the lifetime of the PV cell has expired, although extra cost will be added as a result.

Another difficulty in the scaling-up process is that while perovskite solar cells show high efficiency in a lab with a device size of 10mm x 10mm, the modules used for real applications will need to be much larger. However, in larger modules, the efficiencies drop. For instance, best performing devices generally have a low surface area of < 0.1 cm2. Efficiency dropped by about 30% from 0.1 cm2 to 1cm2 cell area, mostly due to fill factor decrease. However, this can be addressed with time.

The irony is that the two biggest issues – lifetime and toxicity – work against each other. Short lifetime applications (2-3 years), such as consumer and wearable electronics, would preferably use cheap, flexible PV; however, due to the toxicity, glass-based versions need to be used which limit the form factor advantage. Even in glass, they would still need to be recycled at the end of the product life, which is not very practical for high-volume, low-cost electronics. In contrast, long-term fixed installations, such as BIPV, using toxic materials can be acceptable provided they undergo managed recycling, but here current perovskites struggle to work long enough for such applications. Successfully tackling these issues could result in a large opportunity for perovskites. Failing to do so may see the opposite.

Perovskite solar technology is still young but has enormous potential. New material systems, good barriers, better stability, and non-toxic material research work are ongoing. And the bottom line is, those companies addressing some of the aforementioned issues will carve out a significant market share.

Dr. Xiaoxi He is a technology analyst for IDTechEx Research. Established in 1999, IDTechEx provides independent market research, business intelligence, and events on emerging technology to clients in over 80 countries. IDTechEx is headquartered in Cambridge UK; additional offices are in Berlin, Boston and Tokyo.

IDTechEx Research | http://www.idtechex.com

Return to: 2015 Feature Stories