Feature Story

More feature stories by year:

2024

2023

2022

2021

2020

2019

2018

2017

2016

2015

2014

2013

2012

2011

2010

2009

2008

2007

2006

2005

2004

2003

2002

2001

2000

1999

1998

Return to: 2018 Feature Stories

Return to: 2018 Feature Stories

CLIENT: ADESTO

Sept. 12, 2018: EE Times

TORONTO — With the automotive market presenting potential opportunities of ever-emerging memories such as ferroelectric RAM (FRAM), magnetoresistive RAM (MRAM), and resistive RAM (ReRAM), Adesto Technologies is working hard to make sure that the latter makes the grade.

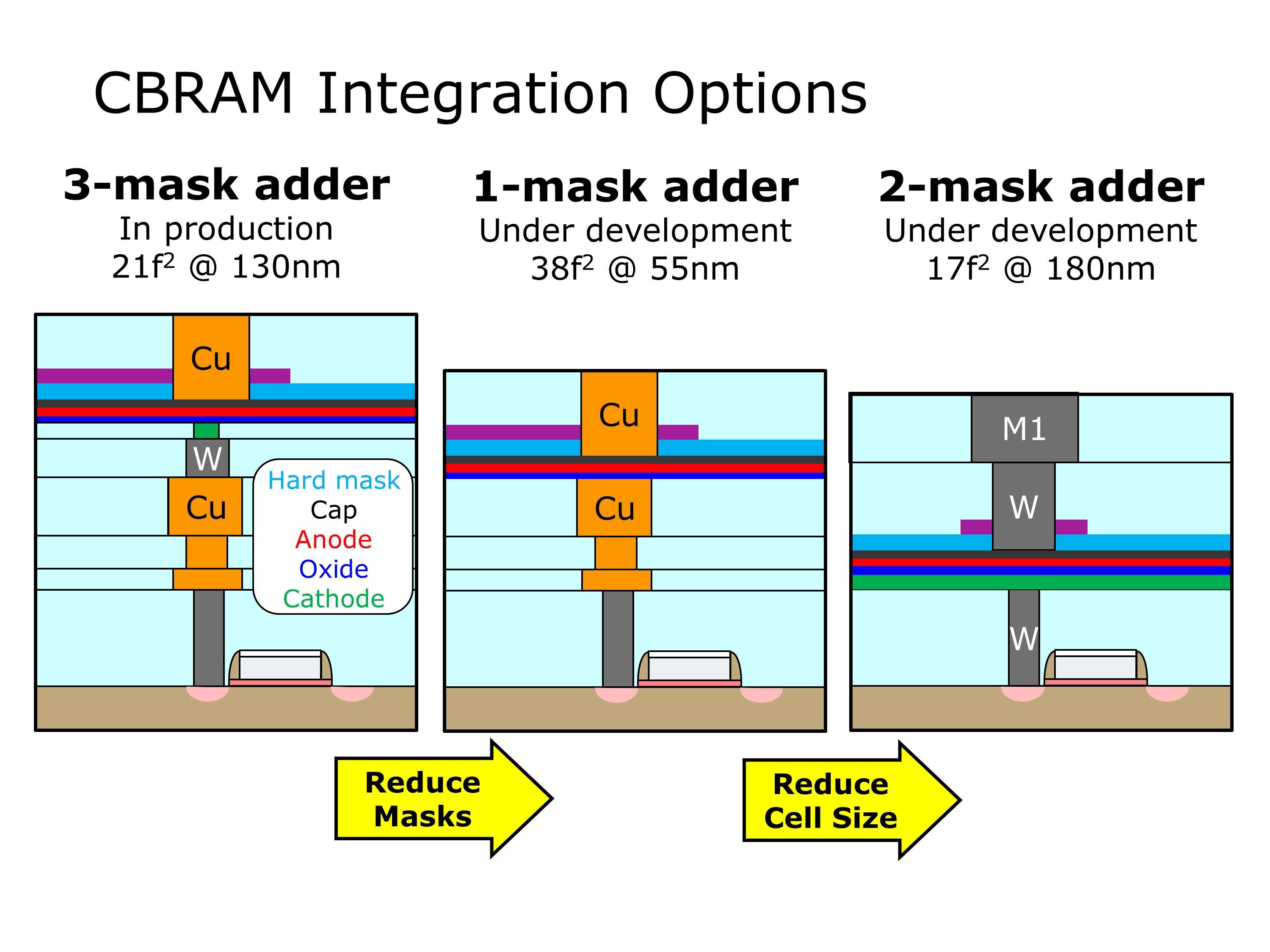

It recently unveiled new research demonstrating the potential of ReRAM for high-reliability applications such as automotive. The research was led by Adesto Fellow Dr. John Jameson, who shared the results at the ESSCIRC-ESSDERC 48th European Solid-State Device Research Conference earlier this month, and indicates that ReRAM could become a widely used, low-cost, and simple embedded non-volatile memory (eNVM) because it uses simple cell structures and materials that can be integrated into existing manufacturing flows with as little as one additional mask.

While Adesto was one of the first companies to bring commercial ReRAM devices to market with its trademarked CBRAM technology that consumes less power, requires fewer processing steps, and operates at lower voltages as compared to conventional embedded flash technologies, ReRAM still faces integration and reliability challenges, which the researchers tackle in their paper.

“Towards Automotive Grade Embedded ReRAM," is authored by Jameson and a dozen collaborators and will be published on the IEEE Xplore website. It describes an improved subquantum conductive bridging RAM (CBRAM) cell, whose reliability appears robust enough for automotive applications, and discusses the main types and levels of errors observed in the new cell stack. The researchers also outline the reliability models that were developed to predict endurance and storage lifetimes.

ReRAM has long been considered a natural successor to embedded Flash (eFlash) for MCUs and SoCs, note the researchers, as it uses simple cell structures and materials that can be integrated into an existing logic back-end-of-line (BEOL) using as few as one additional mask and few, if any, alterations to the front-end-of-line (FEOL), unlike eFlash, which requires 10 or more additional masks as well as a coordinated FEOL/BEOL integration scheme capable of accommodating its high thermal budget.

Another compelling reason to use ReRAM in embedded applications such as automotive is that eFlash is starting to encounter limitations as to how far it can shrink, said Adesto CTO Gideon Intrater. In a telephone interview with EE Times, he said that there’s a lot of room for shrink with CBRAM. “The big question is: Can that technology be executed simply for the automotive industry with the high standards? That’s what this paper is trying to show — that we can actually build products that will have the right level of quality for the automotive industry.”

The paper’s reliability models predict that a storage lifetime of more than 20 years at 150°C following 104 direct write cycles is achievable for a median part failure probability of 1 ppm. That being said, Intrater didn’t want to make any predictions to how soon Adesto’s CBRAM would be replacing eFlash in automotive applications. There’s still a commercialization stage that needs to happen to make it a reality.

The paper estimates that “compared to an existing commercial-grade eNVM at 55 nm, a product built using a 55-nm automotive-grade CBRAM macro could result in a 5% to 20% cost savings per die, accounting for relative macro size, extra masks and process steps, and the relative area ratios of logic to memory.”

Jim Handy, principal analyst with Object Analysis, said that a recurring theme is that companies that make emerging memory technologies are saying that they have a technical benefit that people will be willing to pay a higher price for, and because their manufacturing costs are higher, they must sell them for a higher price. “But at the end of the day, there are not that many applications that can stomach a higher price in return for better performance.” He said that it’s too early tell with ReRAM for this application. “There are two things at play. One is how cheaply it can be manufactured when it’s in high volume, and the other is what kind of volume it’s in right now.”

But Handy said that there is a contest between MRAM and ReRAM to see which one might replace flash in SoCs — usually NOR flash, which has been tried and tested but hitting limitations. He said that Adesto is likely hoping that the market develops, which will, in turn, drive down the price and open the market further, allowing for prices to further drop. “The way it’s going to shape up is that embedded memories are going to be the proving ground that causes the prices and the cost to be driven out of one of these technologies.”

Adesto is not the only company that’s looking to widen the applications for ReRAM. While its CBRAM has found use in medical applications thanks to its radiation tolerance and is addressing power challenges with IoT devices, Israel-based Weebit Nano recently produced the first packaged units containing memory arrays based on its silicon oxide Resistive RAM (SiOx ReRAM) technology. The company said that this enables it to ship its memory technology to partners and is an important step in productization and commercialization efforts. The first memory chips will be delivered to universities to research the use of ReRAM technology in neuromorphic computing.

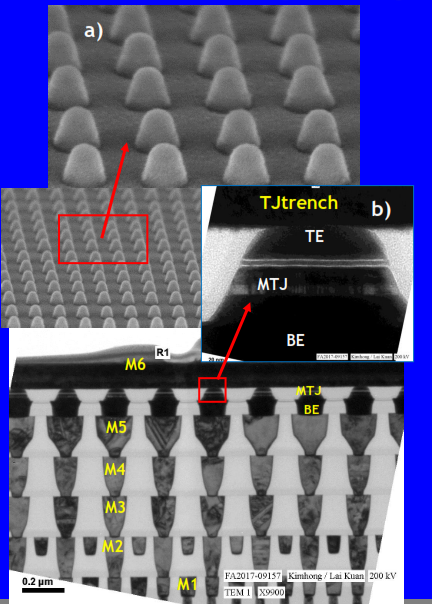

Meanwhile, Everspin Technologies and GlobalFoundries demonstrated last year that embedded MRAM could retain data through solder reflow at 260°C and for more than 10 years at 125°C, plus read/write with outstanding endurance at 125°C, enabling it to be used for general-purpose MCUs and automotive SOCs.

Return to: 2018 Feature Stories